Roller Shutter Roll Forming Machine 40 Working Days T/Tmanufacturer

Product Overview

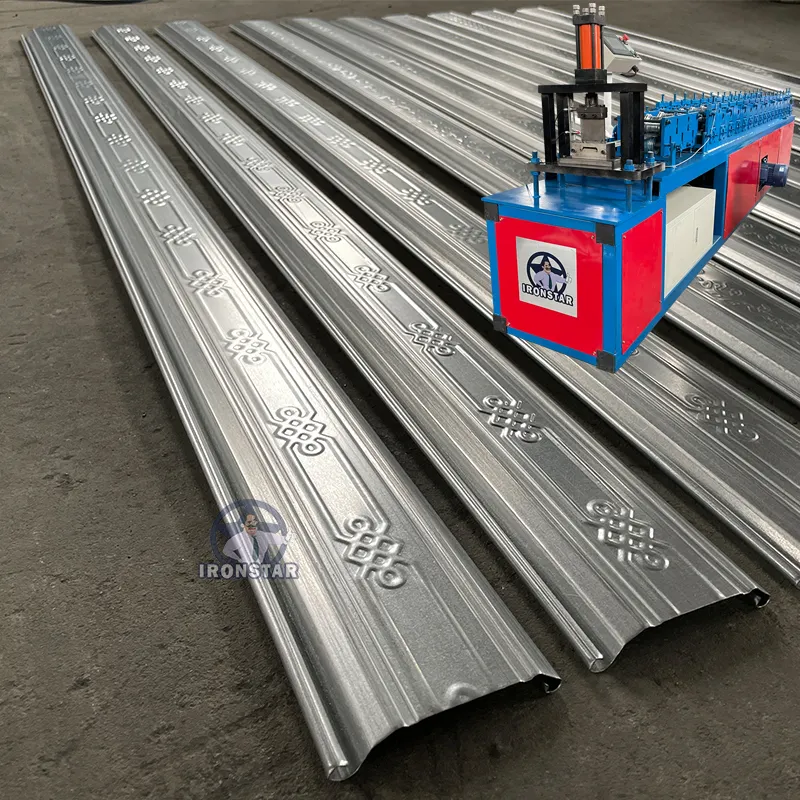

The roller shutter roll forming machine is designed with innovation and quality in mind, ensuring a unique and reliable product. It features a work flow that includes a decoiler, roll forming machine, control computer, product cutter, and receiving table.

Product Features

The machine is able to work with GI (Galvanized Iron) material with common dimensions and thicknesses. It comes with a 3-ton manual decoiler and has a roller station with 14 rollers. The machine frame is made of steel plate welding, and it includes a hydraulic tracking cutting system.

Product Value

The machine is built with high-quality materials and components, ensuring durability and efficiency in production. It offers a cost-effective solution for manufacturing roller shutter doors, providing value for money in the long run.

Product Advantages

The roller shutter roll forming machine has a working speed of 8-20 m/min, making it efficient for production. It also includes a receiving table for collecting finished products and comes with a warranty of 36 months for replaceable parts.

Application Scenarios

This machine is suitable for companies involved in the manufacturing of roller shutter doors. It can be used in a variety of industries that require the production of high-quality and reliable roller shutter products.