Roller Shutter Door Making Machine 20 Feet 40 Working Daysfor Sale

Product Overview

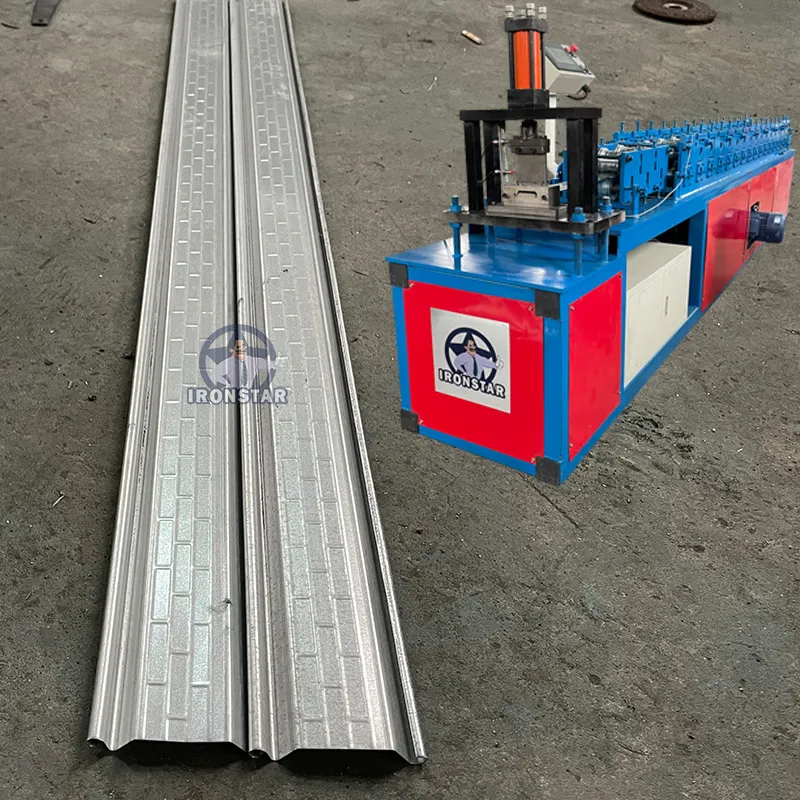

- The product is a roller shutter door making machine designed for producing shutter doors using galvanized iron materials.

- The machine includes a decoiler, roll forming machine, control computer, product cutter, and receiving table.

- It has a roller station with 14 rollers and a diameter of 55mm, capable of producing shutter doors in various sizes.

Product Features

- The machine has a manual decoiler that can stand 3-ton coil materials and a hydraulic tracking cutting system for precise cutting.

- It has a working speed of 8-20 m/min and is powered by a 5.5 KW motor and a 3 KW oil pump motor.

- The machine frame is made of steel plate welding with a thickness of 16mm for durability.

Product Value

- The product offers high-quality production of shutter doors with reliable performance and long service life.

- It provides competitive prices and fast delivery to meet customer needs effectively.

- The machine includes a warranty of 36 months, with free replaceable parts during the warranty period.

Product Advantages

- The machine can produce shutter doors in various sizes and thicknesses, suitable for different applications.

- It is equipped with a manual stacker receiving table for easy collection of finished products.

- The machine is customizable in terms of voltage, color, and language for customer convenience.

Application Scenarios

- The roller shutter door making machine is suitable for manufacturing businesses, construction companies, and contractors producing shutter doors for commercial and residential buildings.

- It can be used in workshops, factories, and construction sites for efficient production of high-quality shutter doors.

- The machine is ideal for customers looking for a durable and reliable solution for producing shutter doors quickly and effectively.