Professional Capping Roll Forming Machine for Building

Product Overview

- Professional Capping Roll Forming Machine for Building

- Warmly welcomed at home and abroad for its fabulous design and optimum quality

- Years of successful experience in manufacturing capping roll forming machines

Product Features

- Roll Forming Line includes Decoiler, Roll Forming Machine, Control Computer, Product Cutter, and Receiving Table

- Commonly uses PPGI material with varying thickness and width

- Manual decoiler with 5 ton capacity, can be upgraded to hydraulic decoiler

- 14 roller stations, hydraulic cutting, working speed of 8-20 m/min

- Machine frame made of 350 H-beam, machine cutter and roller made of 45# steel with chrome coating

Product Value

- Package includes moisture-proof and anti-corrosive guarantee during transportation

- Payment term of 30% deposit via T/T, 70% post inspection

- Delivery time of 40 working days after receipt of deposit

- Technician can be sent to fix the machine at buyer's country at additional cost

- 36-month warranty with free replaceable parts during warranty period

Product Advantages

- Globally competitive company with a focus on capping roll forming machines

- Professional team for quick response and guidance on product inquiries

- Skilled workers and strong technical force for creative production solutions

- Environmentally and socially aware approach towards production

Application Scenarios

- Widely used in various industries for building and construction purposes

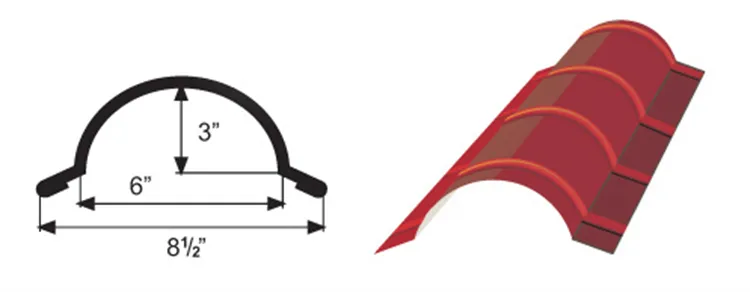

- Suitable for manufacturing different types of building materials such as ridge caps

- Can be customized for specific product requirements

- Ideal for companies looking for high-quality and efficient roll forming machines

- Suitable for countries looking for innovative and advanced building technologies