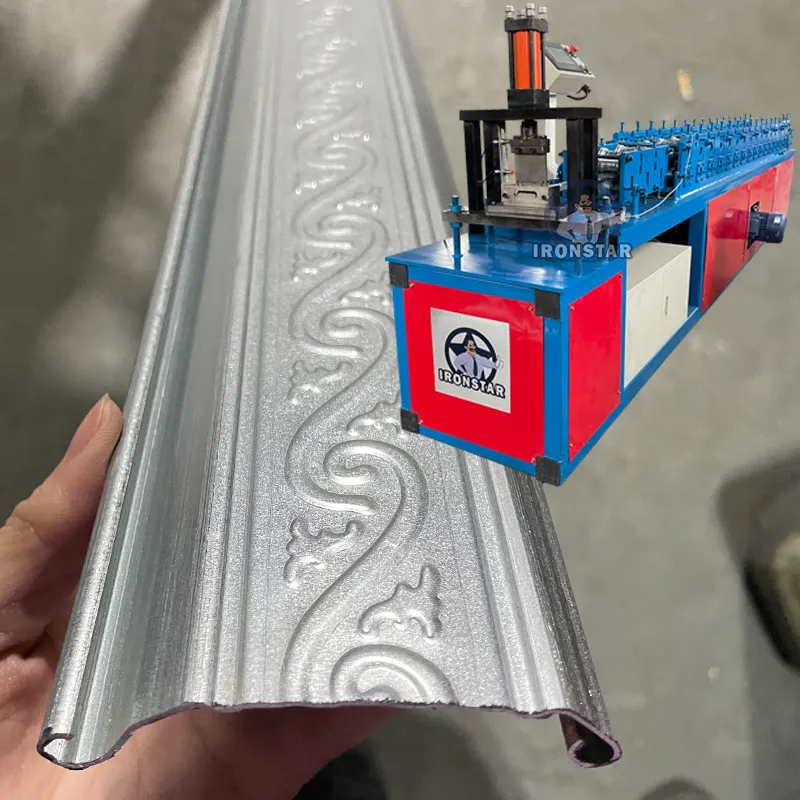

IRONSTAR Shutter Door Roll Forming Machine 20 Feet Container Shutter Door Roll Forming Machinefor Sale

Product details of the shutter door roll forming machine

Product Information

shutter door roll forming machine is specially designed to gain certain function. Buying our competitive-priced shutter door roll forming machine doesn't mean that qulaity is not reliable. The product is the most potential product for growth in the industry.

Product display

Work Flow

Roll Forming Line Include : Decoiler - Roll Forming Machine - Control Computer - Product Cutter - Receiving Table

Diameter Of Roll Forming Machine

Raw Material

This type shutter roll formng machine common use GI ( Galvanized Iron ) Material,

Material width before roll forming depend on product drawing

Material thickness common 0.6-1.2 mm

One roll common is 500- 700 kg weight

We list common used shutter door size and about width for you reference

Shutter Door Size | Material Width/mm | Material Thickness /mm | 1 Ton Material Length / m |

| 80 mm | 110 | 0.6 | 1930 |

| 80 mm | 110 | 0.8 | 1447 |

| 80 mm | 110 | 1 | 1158 |

| 90 mm | 126 | 0.6 | 1685 |

| 90 mm | 126 | 0.8 | 1264 |

| 90 mm | 126 | 1 | 1011 |

| 100 mm | 151 | 1.5 | 1406 |

| 100 mm | 151 | 0.8 | 1054 |

| 100 mm | 151 | 1 | 844 |

| 120 mm | 160 | 0.6 | 1327 |

| 120 mm | 160 | 0.8 | 995 |

| 120 mm | 160 | 1 | 796 |

Manual Decoiler

This machine use 3 ton manual decoiler , it can stand 3 ton coil material

Work with roll forming machine together, feed material into machine

This type is manual type, when buy machine, send customer free as gift

If you want more automatic type, can choose Hydraulic decoiler

Machine Specification

| Roller Station | 14 |

| Diameter of Shaft | 55 mm |

| Shaft Material | 45# steel with 0.05mm chrome |

| Roller Material | Cr 12 |

| Machine Frame | Steel Plate welding |

| Frame Thickness | 16 mm |

| Machine Cutter | Hydraulic Tracking Cutting |

| Working Speed | 8-20 m/min |

| Driving Way | Chain 1 inch |

| Motor Power | 5.5 KW |

| Oil Pump Motor Power | 3 KW |

| Machine Size | About 4.5×1.5×1.3 m |

| Machine Weight | About 1.5 ton |

| Machine Voltage | 380V 50HZ 3P, or customize as your need |

| Machine Color | Common Blue, or customize as your need |

| Machine Language | Chinese, English, or customize as your need |

Receiving Table

| Table Length | 3m |

| Operataion | Manual Stacker |

Receiving table use to collect finished product

When finish work, you can use forklift take it away

Package & Payment & Service

1). Packing method: Nude, seller should guarantee equipment will be moisture-proof, anti corrosive, and will not be damaged during transportation.

2). Payment Term: 30% of total contract value paid by T/T, last 70% paid by T/T after inspection by buyer in seller’s factory while before delivery.

3). Delivery Time: The seller guarantees the equipment will be ready for shipment within 40 working days after receipt of deposit from the buyer.

4). Service: We could send technician to your country to fix the machine if you need. The buyer need to pay for all the cost, including: visa, round trip tickets, accommodation, salary of USD 120 per day.

5). Warranty: 36 months During warranty, the replaceable parts are free, but the buyers need to pay for the shipping fee.

We Sell to Country

Company Advantage

• Since founded in IRONSTAR has been developing for years. Now we become the leader in the industry.

• IRONSTAR has a high-quality management team, excellent R & D team, intimate service team, and also set up a professional distribution team to provide a good guarantee for product development, sales services, transportation, and distribution.

• The natural resources around IRONSTAR are abundant. The geographical condition is excellent which brings developed information and traffic convenience.

• IRONSTAR's products are mainly exported to Europe, America, Asia and Africa and other countries and regions.

IRONSTAR is a pharmaceutical company that values integrity and reputation greatly. Machines are of good quality and affordability. If you have any needs, you may contact us directly.