High Quality Omega Clamp Roll Forming Machine Factory for Building

Product Overview

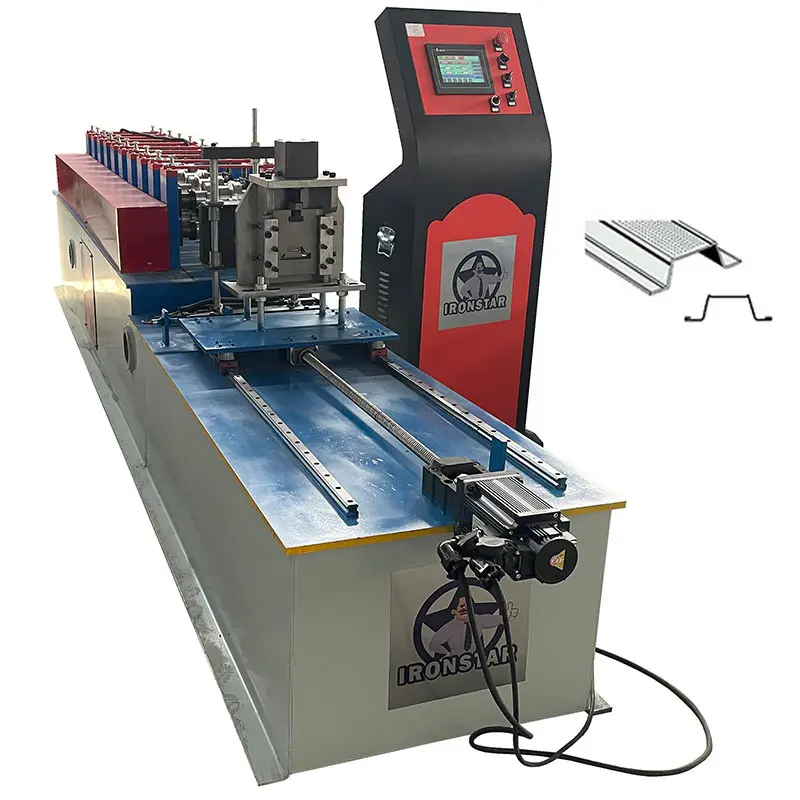

- The product is a high-quality Omega Clamp Roll Forming Machine designed for building construction.

- The machine has a roll forming line that includes a decoiler, roll forming machine, control computer, product cutter, and receiving table.

- The machine is designed to work with GI (Galvanized Iron) material with various dimensions and thicknesses.

- It comes with a manual decoiler that can handle 3-ton coil material and a hydraulic tracking cutting machine cutter.

- The machine has a working speed of 30-50 meters per minute and requires a motor power of 4 KW.

Product Features

- High-quality construction with reliable performance.

- Can work with GI material of various sizes and thicknesses.

- Manual decoiler included with the machine.

- Hydraulic tracking cutting for precision cutting.

- Technical training for customers provided for free.

Product Value

- The machine offers uninterrupted and fine production process.

- Comes with a COA for quality assurance.

- Free technical training for customers.

- Prompt and high-quality services provided.

Product Advantages

- High-quality construction ensures long-term excellent performance.

- Can handle a variety of GI material sizes and thicknesses.

- Manual decoiler included as a gift with the machine.

- Hydraulic tracking cutting for precision cutting.

- Sold to both domestic and foreign markets.

Application Scenarios

- Ideal for building construction projects.

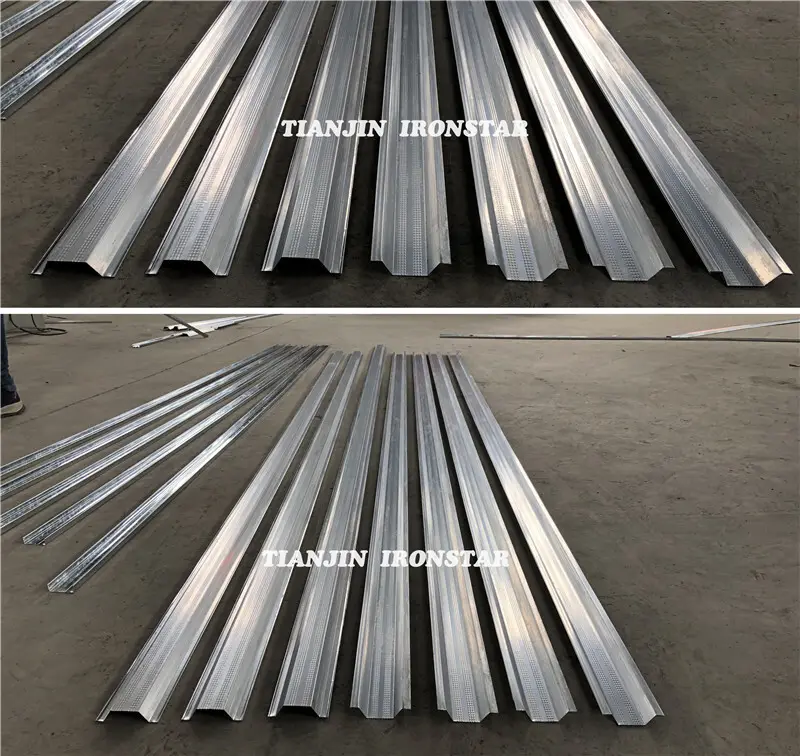

- Can be used in the production of Omega clamp channels of various sizes.

- Suitable for companies looking for a reliable and high-performance roll forming machine.

- Can be used for producing high-quality building materials efficiently.

- Suitable for companies looking to enhance their production process with a reliable machine.